Tackling Industry 4.0 challenges

Currently, there is a significant transformation happening in the way goods are produced and delivered. The world is moving toward industrial automation and a factory that is more adaptable to change. That’s what Industry 4.0 is all about. Factories and warehouses are becoming more agile and efficient through digitalization. That is needed in order to stay competitive. Making machines smarter, processes less wasteful, production lines more flexible is the way to go. Industry 4.0 opens many doors to this.

How to get started?

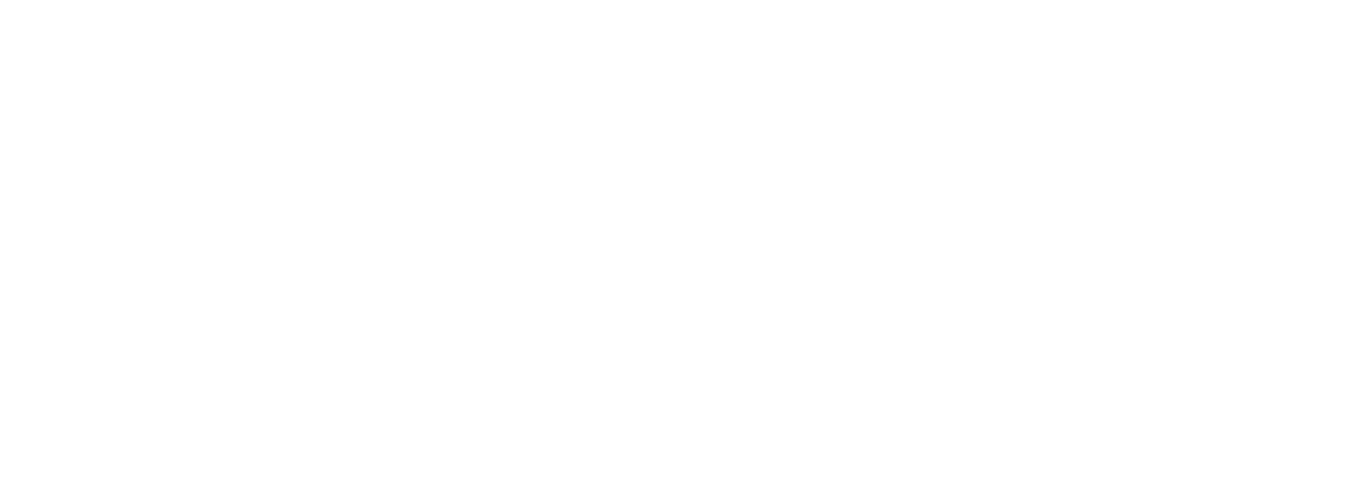

If you want to hop on the Industry 4.0 train, it is important to have a very small use case in mind. At Itility, we employ a three-step approach: narrow down your use case, engineer the system and data, and keep factory operationalization in mind when designing your solution.

Narrowing down your use case means examining your data and selecting a small but viable use case that directly adds value to your business and that can be implemented in a short period of time. Engineering the system implies designing what tools, techniques, and integrations are needed for each step in the process. This gives you an end-to-end overview of everything required for your use case and allows for a detailed planning.

The final step of solving your use case is to embed it in your daily processes. Challenges will arise every step of the way. The key here is not trying to solve everything at the same time but to keep taking small steps forward toward the end goal. Want to read more about this approach? Check out our blog: Business value from data use cases: a three-step approach.

Below are two examples of how we apply this at our customers.

Smartifying products

One of our customers, AMF, makes advanced mechanical bakery systems, including pizza production lines that make up to 12,000 pizzas per hour. Together with AMF, we created a digital solution to help pizza producers save money by reducing so-called cheese giveaway (more cheese on the pizza than specified): the Smart Cheese Applicator. The use case was small (reduce cheese waste on a pizza). We engineered the system to a fully digital solution that automatically detects when too much cheese is spread on each pizza and then automatically adjusts the belt speed of the cheese applicator.

In summary, the solution works like this: a camera setup with motion sensors takes a photo of each pizza and sends it to an edge computer near the production line. A weight sensor would not have worked in this setup due to the high number of pizzas per hour, the vibrations of the belt, and how the production line is cleaned with water several times during the day. The camera setup enables the early signaling of problems in the cheese distribution as well as quality control on all pizzas instead of on just a sample set. Manual control decreases, standardization and consistency increase.

Another part of the setup is an algorithm that detects the amount of cheese via a trained image recognition model. If the cheese ratio deviates from specification, a signal is sent to the HMI and operator to adjust the conveyor belt speed via the PLC. With this solution, AMF’s customers can save hundreds of thousands of euros on cheese (the most expensive ingredient on a pizza). We put a bare-bone version of this system to work at one of AMF's customers, having their operators use it on a day-to-day basis and finetuning it based on their feedback.

Smartifying the factory

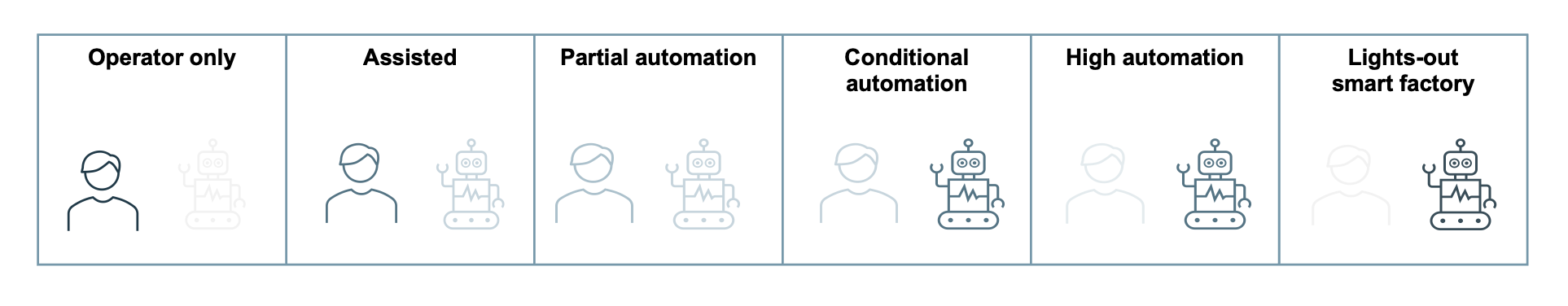

Another one of our customers is transforming from analog operations based on expertise and craftsmanship into a remotely controlled smart factory based on systems and data. This type of smart factory is a highly digitized shop floor. It continuously collects and shares data through connected machines, devices, and production systems.

Our job is to automate use case by use case — by looking for answers to questions such as what the processes in an automated factory will look like, what systems are needed to get the factory running via remote control, how to fit operators, robots, automation, and remote engineers into this picture, and more.

The journey to a smart factory is a lengthy one, so you cannot aim for this in one go. And it seems like a no-brainer but still, Industry 4.0 projects focus too much on technology. But just technology won’t make a working factory: systems integration is key. So, combining OT and IT to control the factory.

Conclusion

The high pressure of today’s environment to improve production lead times, increase quality and maintain margins — all while remaining profitable — makes changes in factory operations inevitable. Industry 4.0 offers many ways to smartify the way of working within manufacturing. For example, by making the machine smarter, by making the systems in the factory smarter, or by making the processes smarter.

Right now is the time to start acting on this. Just remember to make it small, one narrow use case at the time. Engineer the system and data to integrate all moving parts and embed the new way of working in your day-to-day processes.