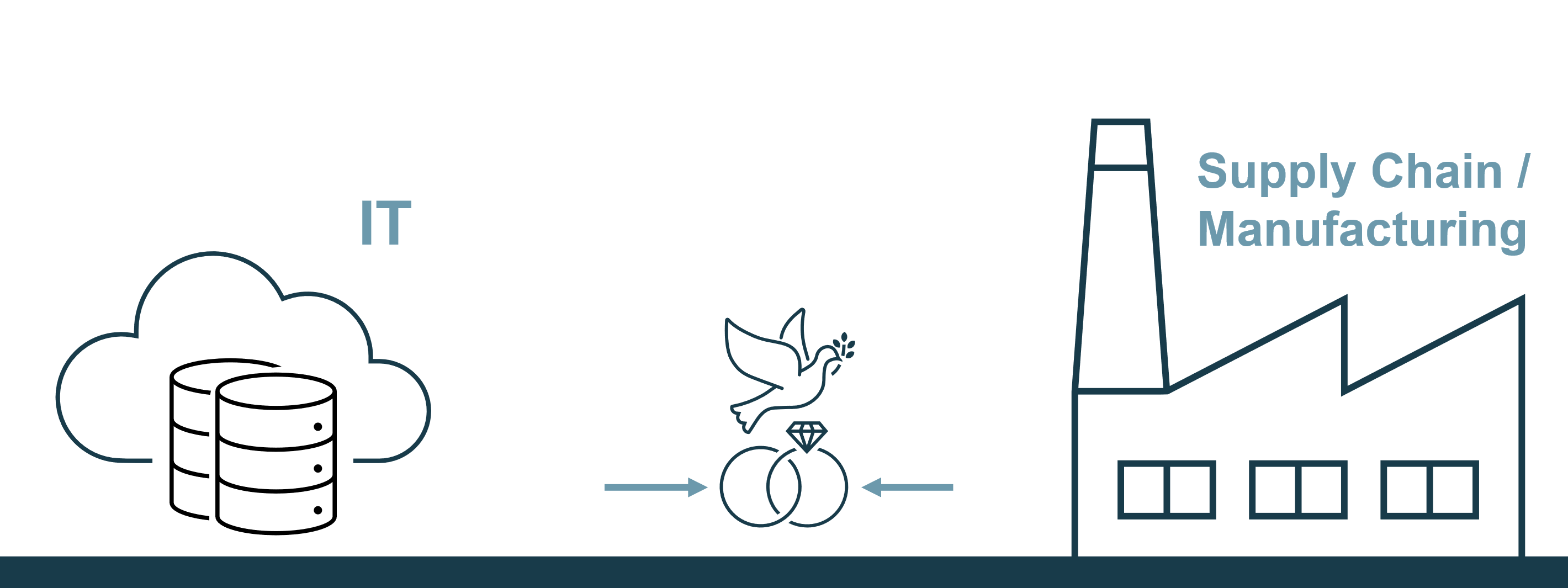

Marrying IT & the factory

Over time, we have seen the role of IT in manufacturing organizations change. IT has always been an enabler for the basics: IT as utility, the essential “plumbing” to keep an organization running. However, IT and Digital have evolved into a critical success factor for manufacturing and supply chain performance. Instead of an enabler, it became a potential competitive advantage for organizations who are doing it right.

Think about it: after we fixed our cloud, infra, security, and workplace fundamentals - IT started having an impact on output, cost, resilience, flexibility, and quality; things that directly impact your bottom line. Over the years we have digitalized almost everything through systems such as PLM, ERP and MES. We have all been working on optimally leveraging data, software, and AI. Think of predictive maintenance, automation, and quality control in our factories, and demand forecasting, control towers, and scenario simulations in supply chain. IT has become an indispensable component for business success.

In short: IT and the factory finally got married

And just like a real marriage, we see that collaboration between IT and manufacturing is hard work. IT struggles with unclear requirements, unrealistic expectations or a shifting scope, while the business is having a hard time in communicating its demand and need for flexibility to IT.

Success factors for a good marriage

So, let’s have a closer look at the success factors for a good marriage – in general and particularly between these two worlds. As an example, we’ll be referring to a project that we’ve done with one of our customers: the Supply Chain Assistant (SCA). The SCA is a digital twin that helps to make forward-looking supply chain decisions by modeling, predicting, and simulating scenarios across a full supply chain.

1. Understand each other’s worlds

Key in every marriage: understand each other. Learn about each other’s worlds, challenges, and needs. For IT this means: go to the shop floor! See how the factory works in practice, experience what an operator needs to do his work or what makes an S&OP process challenging. Get away from that desk.

For manufacturing and supply chain stakeholders, our main advice: get curious about how IT really works. Don’t see it as a magic technology that solves all your problems, but learn what it can bring you and what not, and what it takes to implement something. Curiosity is everything.

This is how our SCA project started. We had a former supply chain executive wondering: “how can I get more out of AI?”, and several data scientists eager to learn about the world of supply chain. The result: an AI-driven digital twin that can directly be applied to supply chain operations.

2. Quality time

No relationship works without quality time. Same here: don’t work in two separate silos and treat each other as a distant customer or supplier, but do it together. Create teams that combine IT and Operations expertise, bring business-oriented IT engineers and IT-minded manufacturing people together in the same team. And let them focus on one goal. It’s the only way to truly collaborate.

In our SCA project, this was a big enabler for the eventual success. Instead of supply chain stakeholders waiting for the tool to be developed, we worked together - to bring a realistic view of the supply chain dynamics into a model. Leading to a model that does not only work in theory, but also in real life.

3. Link a digital transformation strategy (top down) to shop floor reality (bottom up)

Okay, this one doesn’t apply to a marriage, but it’s essential anyway. We see many digital ventures starting from a grand vision but never reaching the shop floor; or the other way around: great engineer-driven initiatives which don’t add up to the corporate strategy. For us this is always a key activity: create a digital transformation strategy that defines how digital should contribute to the bottom line, and then link it to specific initiatives that improve life in daily operations.

Same for our SCA project: an important reason for success is that it takes challenges, wisdom and experience from planners and shop floor operations, and then connects it to a C-level vision of a global, controlled, predictable supply chain.

4. Fights are okay – as long as you make up

And last but not least: a marriage without fights doesn’t exist. Bringing together IT, manufacturing, and supply chain is “a journey”. What distinguishes organizations who do this well? Perseverance. So, don’t forget to make up next time you’re in an intense discussion with IT or business.

.png)